The Power of Automated Quality Traceability System in EMS

In the highly competitive world of electronics manufacturing, companies are constantly seeking ways to improve their operations and meet customer requirements while adhering to regulatory standards. Maintaining high quality standards and ensuring on-time delivery besides addressing the issues related to component and assembly traceability has become very critical to achieving excellence in operations, performance, and overall business. With the advancements in technology, many electronics manufacturing companies are turning towards smart processes to streamline operations and improve efficiency; and one such solution that has gained prominence in recent years is the Automated Quality Traceability System (AQTS).

The importance of traceability in electronics manufacturing

Traceability is simply the ability to identify products, components, and processes throughout the manufacturing lifecycle and track the production of products from start to finish. This includes tracking the materials used, the production process, and the testing and quality control measures that are in place.

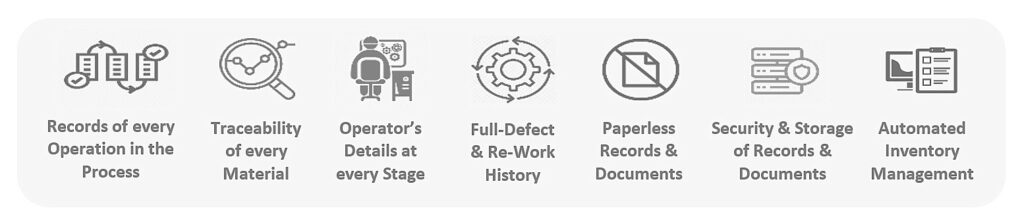

In the electronics industry, implementing a smart in-house traceability and quality system offers numerous benefits and allows manufacturers to identify potential issues, rectify them promptly, and minimize the risk of product recalls. Employing Automated Quality Traceability System results in:

- Improved quality control: By tracking materials and components throughout the production process, companies can quickly identify and address any defects that may arise, leading to higher-quality products.

- Enhanced efficiency: The use of technology such as barcoding and RFID tags streamlines the production process and reduces the risk of errors or delays, thus addressing customer needs effectively.

- Cost savings: By catching defects early in the production process, companies can reduce the need for costly recalls and rework, ultimately saving money.

- Regulatory compliance: In the electronics manufacturing industry, traceability is a legal requirement. Implementing a robust in-house traceability and quality system ensures that companies meet all regulatory requirements.

AQTS at Vinyas

Understanding the significance of transparency, accountability, and visibility in the operations process, Vinyas has swept all the challenges related to product traceability by adapting the Automated Quality Traceability System. Through this AQTS software tool, Vinyas has been able to trace the products and components throughout the manufacturing/assembling process, capturing detailed information about each stage of production, including machine and operator details. This level of detailed transparency and real-time data access not only has benefited the Vinyas team but also has provided valuable insights to the customers to generate various reports for analysis, thus further enhancing decision-making capabilities for better outcomes.

Key benefits of AQTS for Vinyas

Along with building linearity with customer requirements and regulatory standards; establishing a solid traceability system has helped Vinyas to reap operational benefits.

One of the key advantages of having a robust traceability system in place is the benefit of having access to real-time data. Besides the ability to track products, components, and processes at every stage of manufacturing, this real-time visibility has helped us to identify potential issues, reduce errors, take corrective actions promptly, minimize waste, and optimize resource utilization. Having streamlined manufacturing processes has resulted in improved efficiency, reduced costs, and faster time-to-market.

Secondly, AQTS has enabled Vinyas to align with customer requirements and meet regulatory standards effectively. By having a complete picture of the product journey, we are able to quickly address customer queries and provide accurate information about the products we manufacture. This prompt responsiveness has helped us build trust and credibility, in turn resulting in increased customer satisfaction.

In addition to complying with regulatory requirements and customer expectations, AQTS has aided Vinyas in reaping operational benefits by reducing the risk of non-compliance penalties and ensuring smooth audits. By streamlining processes, reducing errors, and improving efficiency, Vinyas has saved time and resources, ultimately leading to reduced costs and increased profitability.

Conclusion

Overall, smart processes like the Automated Quality Traceability System have proven to be a game-changer and are revolutionizing the electronics manufacturing industry, offering a seamless way to maintain compliance, enhance operational efficiency, ensure quality, and ultimately improve customer satisfaction. As technology continues to evolve, electronics manufacturing companies are leveraging these tools to stay ahead of the competition and deliver superior products and services. With a focus on traceability and quality, EMS providers can achieve operational excellence and drive success in a rapidly changing market.